New Technology Cheese Balls Corn Puff Snacks Chips Making Machine Plant Pillow Core ...

Jinan Saibainuo Extrusion Machinery Co., Ltd.- Automatic Grade:Automatic

- Process:Thermal Processing

- Power Source:Electric

- Certification:CE, ISO9001, BV

- Application:Chips, Puff Snacks Food

- Customized:Customized

Base Info

- Specification:Stainless Steel Food Grade Materials

- Transport Package:Wooden Box Packaging

- Processing:Mixing, Extruding, Drying, Flavoring, Packaging

- Feature:Automatic, Low Consumption, High Quality

- Technology:Extrusion

- Inverter:ABB, Delta

- Motor Brand:ABB, Siemens

- Materials of Machine:Stainless Steel

- Capacity:100-150kg,H, 200-250kg,H, 400-500kg,H...

- Function:Puff Snacks, Corn Snacks

- Raw Materials:Corn Flour, Wheat Flour, Rice Flour etc

- Product Name:Corn Puff Snacks Chips Making Machine

- Model NO.:SLG

- Trademark:Saibainuo

- Origin:China

- HS Code:84388000

- Production Capacity:50 Sets,Month

Description

Basic Info.

Model NO. SLG Product Name Corn Puff Snacks Chips Making Machine Raw Materials Corn Flour, Wheat Flour, Rice Flour etc Function Puff Snacks, Corn Snacks Capacity 100-150kg/H, 200-250kg/H, 400-500kg/H... Materials of Machine Stainless Steel Motor Brand ABB/ Siemens Inverter ABB/ Delta Technology Extrusion Feature Automatic, Low Consumption, High Quality Processing Mixing, Extruding, Drying, Flavoring, Packaging Transport Package Wooden Box Packaging Specification Stainless Steel Food Grade Materials Trademark Saibainuo Origin China HS Code 84388000 Production Capacity 50 Sets/MonthProduct Description

New Technology Cheese Balls Corn Puff Snacks Chips Making Machinery Plant Pillow Core Filling Snacks Production LineBrief Description of Puff Snack Machine

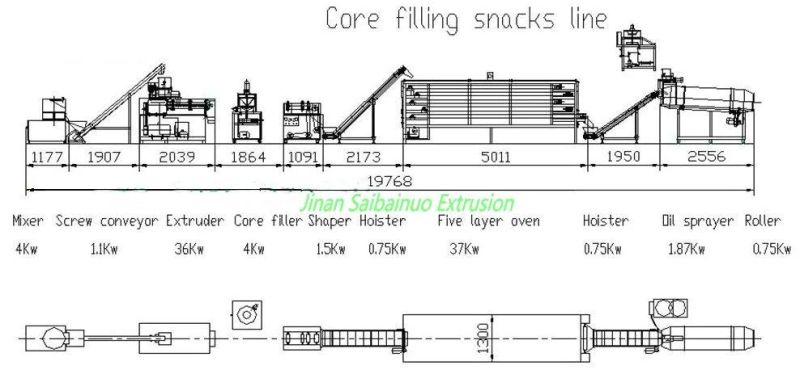

Puff snack machine can use corn flour,rice flour,wheat flour and other grain powder as raw materials, to produce different shape puff snacks by changing the extruder mould, such as chips, ball, ring, stick, flake, flower shapes etc. Puff Snack Machine adopt advanced extrusion technology with high efficiency instead of traditional steam boiling process. It has features of continuous working,stable performance and reasonable design Corn Puff Snacks Machine Process Line Production Flow: Mixer→ Screw conveyor→ Twin-screw extruder→ Air Conveyor→(Core Filling Machine) →Cutting Machine→Gas/Electricity Dryer→Hoister→Oil sprayer→ Flavoring Roller→ Cooling conveyor→Packing Machine

Layout of Corn Puff Snack Machine Core Filling Snacks Process Line

We can design the puff snacks process line and core filling snacks machine layout according to the dimension of customers' factory.

Jinan Quality Corn Puff Snacks Making Machine Processing Line in Workshop

7. Packing & Shipping for Corn Puff Snacks Food Making Machinery:

1.Outside package, fumigation free wooden case

2. Inner packing, stretch film

Delivery Detail:30 working days after order

8.Saibainuo Company before sales service for Puff Snacks Proccessing Line Plant:

a.) We provide you the suitable solution,which is useful and convenient

b.) We produced the product you need in our factory,you can buy it without any hesitate.

c.) We provide you the factory design and processing line layout and also design for water and electric and gas etc.

d.) With much experienced technical team,we can meet customer personalized requirement,produce the customized machine for you

Saibainuo Company after sales service for Puff Snacks Manufacturing Plant:

a.) Consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

9. Saibainuo Company information for Corn Puff Snacks Food Processing Machinery Line

Saibainuo is a leading manufacturer of high quality Twin Screw Extruders for food industries.

We have almost 20 years' experience of working with our customers providing specialist designs

and practical solution for a wide range of process needs.

Saibainuo has a comprehensive manufacturing program offering equipment and systems to customers

in extruded snack food processing machinery and allied industries. We can supply individual items of

equipment or complete factory layouts and lines, which are custom-built to meet the requirements of customers.

Factory standing area:30000 square meters

Workshop standing area:20000 square metersOffice area:4 floor with 600 square meters.

Welcome you come to our factory for visiting. Our company is in Jinan City, Shandong Province, China.