Small Scale French Fries Production Line

Zhengzhou Longer Machinery Co., Ltd.- Automatic Grade:Semi-Automatic

- Process:Thermal Processing

- Power Source:Electric

- Certification:CE, ISO9001

- Application:Chips, French Fries and Potato Chips

- Customized:Customized

Base Info

- Specification:1500*1600*1800mm

- Transport Package:Standard Wooden Packing

- Usage:Making French Fries and Potato Chips

- Material:304 Stainless Steel

- Name:Small Scale French Fries Production Line

- Model NO.:LFM-300

- Trademark:LONGER

- Origin:China

- Production Capacity:20-500kg,H

Description

Basic Info.

Model NO. LFM-300 Name Small Scale French Fries Production Line Material 304 Stainless Steel Usage Making French Fries and Potato Chips Transport Package Standard Wooden Packing Specification 1500*1600*1800mm Trademark LONGER Origin China Production Capacity 20-500kg/HProduct Description

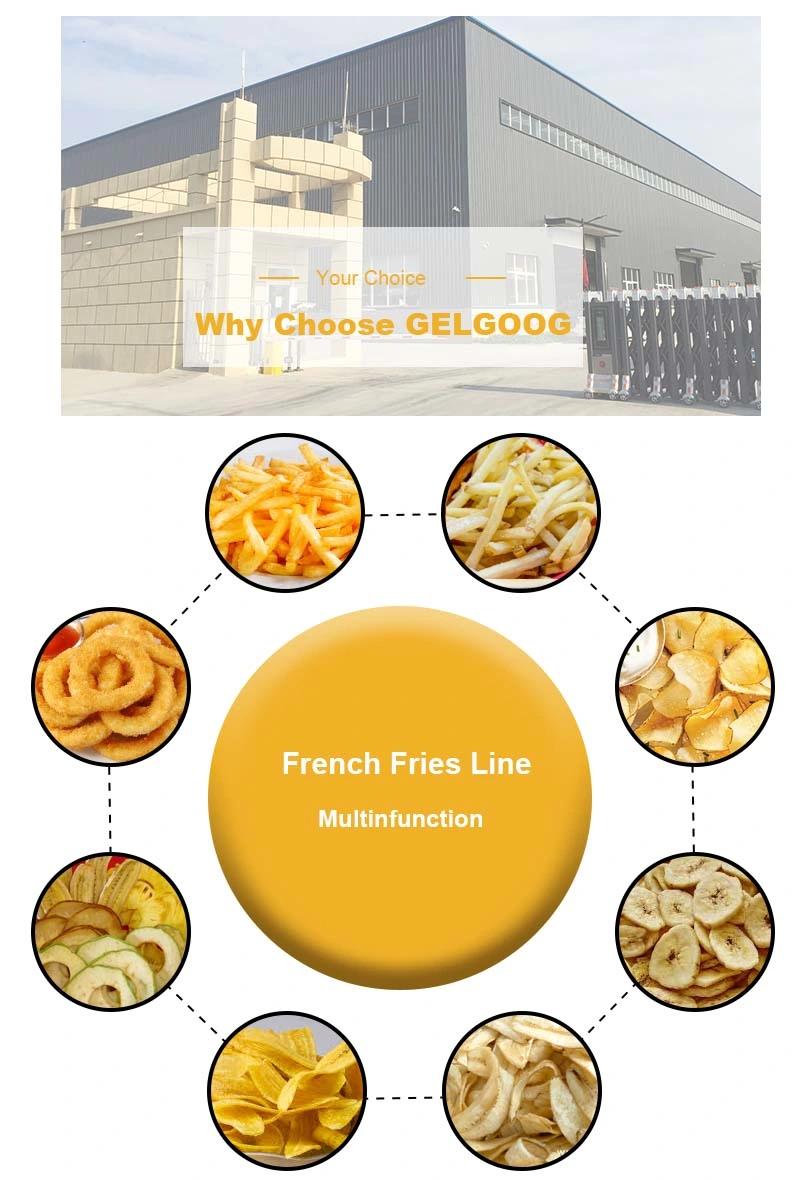

This is a large output French fries production line to produce good quality frozen French fries. It has the advantages of high automation, simple operation and energy-saving. Frozen French fries can be kept longer than potato chips that are the reason why some noshery and restaurant like to cook French fries to sell. This production line can process high quality frozen French fries that comply with health standards. And also we supply small scale french fries line.

Brief Introduction of French Fries Production Line

1. This is a fully automatic production line to produce frozen French fries from fresh potatoes.

2. All the machines in the production line are made of stainless steel 304

3. Electricity power requirement is 380V/50Hz/three-phase.

4. Cutting machine can cut the potato sticks of thickness 2-10mm, it is adjustable.

5. The packing machine is an automatic one and it can feed, elevate, weigh, and pack the fries at one time.

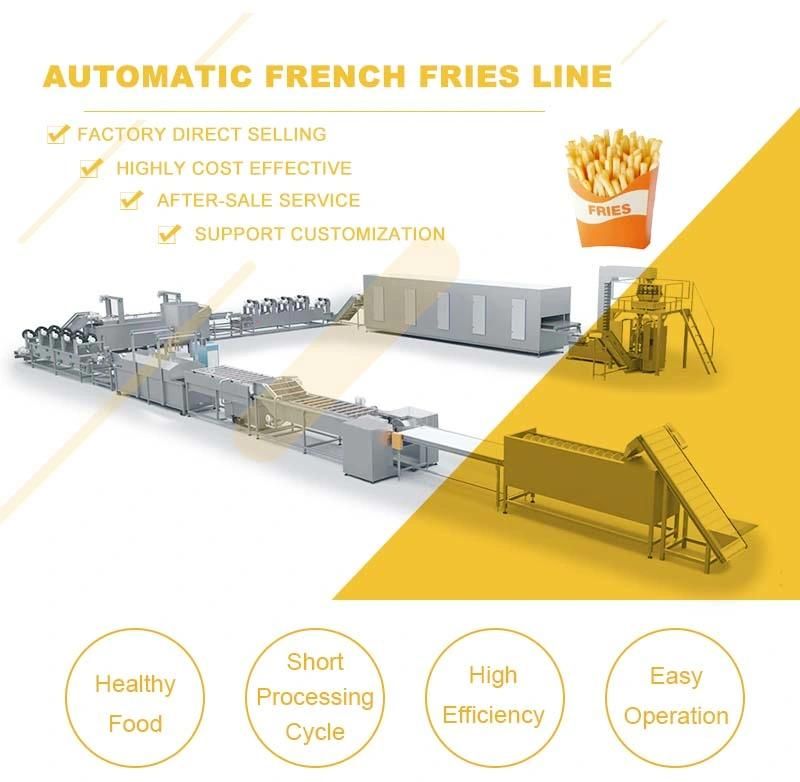

Features of Large-Scale Frozen French Fries Line

1. Various choices. We supply 350-400kg/h, 600-700kg/h and 1000-1200 kg/h for customers.

2. Longer service life. Stainless steel to guarantee a long service life for processing larger quantity of French fries.

3. High efficiency and energy saving. Excellent quality and Low oil consumption.

4.Easy operation and multifunctional usage.

5. Comparative price and high rate of profitable return.

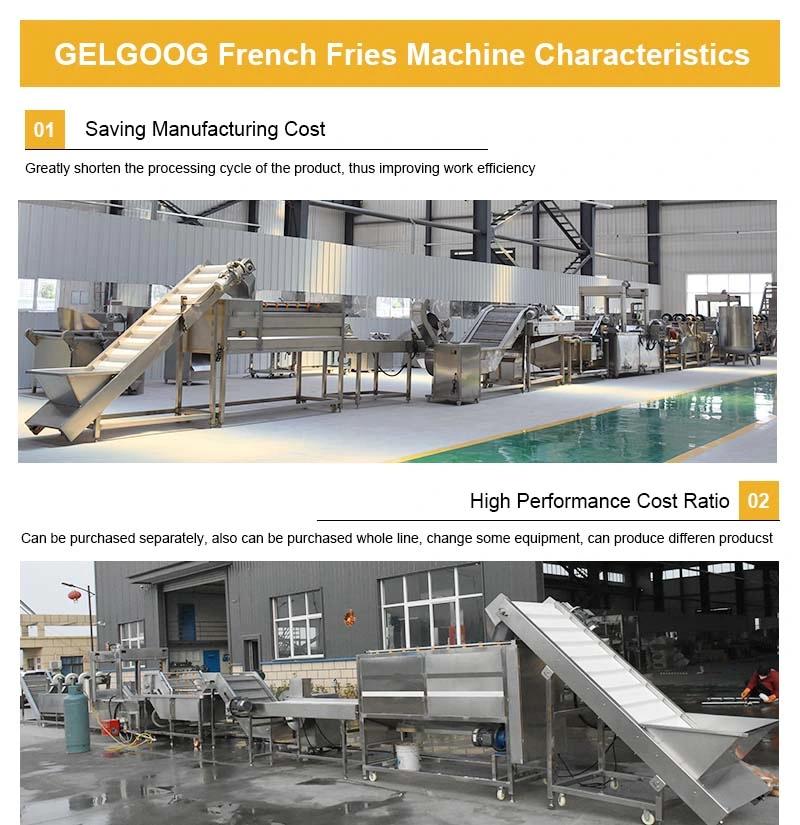

350-400kg/h Automatic Frozen French Fries Line Solution

- The land needed to install the production line is 200 square meters(do not include the freezing part).

- The length of the entire production line is 47 meters(do not include the freezing part).

- Water consumption: 0.3 cubic meters per hour.

- Labor needed: 3-4 (one people work at the beginning of the production line to feed potatoes into the elevator, another two people work at the two choosing machines to choose the unqualified potatoes, and at the packing machine need one people to collect the final packed bags).

- Electric consumption is 155Kw.h(do not include the freezing part).

- Oil consumption is 8 liters per hour(any kind of cooking oil is available, such as sunflower oil, corn oil, bean oil, peanut oil, rapeseed oil, etc.).

Technical Parameter of Automatic Frozen French Fries Production Line

| No. | Machine | Size | Power |

| 1 | Lifting Machine | 2400*900*1600mm | 0.55KW |

| 2 | Potato Washer Peeler | 2800*850*1400mm | 4.37KW |

| 3 | Picking Belt | 2500*900*800mm | 0.75KW |

| 4 | Potato Cutting Machine | 950*800*950mm | 1.1KW |

| 5 | Bucket Hoist | 2200*900*1600mm | 0.75KW |

| 6 | Impurity Removal | 2000*800*1300mm | 2.2KW |

| 7 | Rinsing Machine | 3000*1000*1300mm | 5.25KW |

| 8 | Blanching Machine | 4000*1000*1300mm | 100KW |

| 9 | Vibration Dewatering Machine | 1800*1230*1020mm | 0.5KW |

| 10 | Wind Drying Machine | 3500*900*1600mm | 7.1KW |

| 11 | Lifting Machine | 2000*700*1300mm | 0.55KW |

| 12 | Continuous Frying Machine | 4000*1100*2200mm | 120KW |

| 13 | Vibration Deoiling Machine | 1800*1230*1020mm | 0.5KW |

| 14 | Wind Drying Machine | 3500*900*1600mm | 6.75KW |

| 15 | Lifiting Machine | 3000*900*2100mm | 0.75KW |

| Total | French Fries Production Line | L44M*W4M | 251.12kw |