China Economic Pet Food Extrusion Machine

Shandong Nolen Machinery Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Pet Food

- Customized:Customized

Base Info

- Model NO.:ks65

- Type:Twin-Screw Extruder

- Material:304stainless Steel

- Motor Brand:ABB,Siemens Optional

- Power(W):22kw -110kw

- Voltage:220V,50Hz 380V,50Hz

- Main Motor Power:22kw

- Installed Power:35kw

- Weight:1500kg

- Raw Material:Meat, Cereals, Vegetables, Bone , Fish Meal,etc.

- Function:Dog, Dog,Cat,Fish,Fox or Other Pet Food Production

- Shapes:Stick,Ball,Chunks and So on

- Warranty:1.5 Years

- Date of Delivery:30-45days

- Worker Needed:2-4 Workers

- After-Sales Service Provided:Field Installation, Commissioning and Training

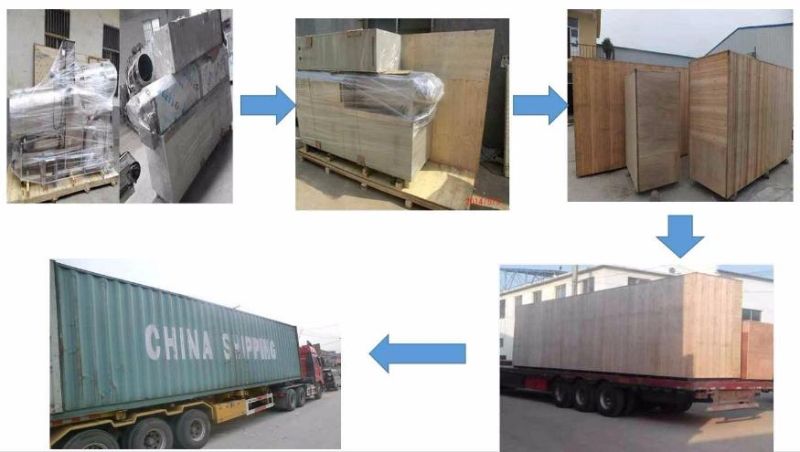

- Transport Package:Wooden Case

- Specification:20000*3000*2600mm

- Trademark:KS

- Origin:Shandong, China

- HS Code:8438800000

- Production Capacity:100-1000kg,H

Description

440/480V

seas

gas-fired burner, steam

Introduction

In order to meet modern fish farms development, most of modern fish feed is made by twin-screw (or single screw) extrusion production line, which is called expanded fish feed. Floating fish feed is the biggest type of expanded fish feed. Adopting cereals, vegetable proteins, vitamins, minerals, fish meal and fish oil as raw materials, and adopting dry-type or wet-type extrusion as manufacturing technique, floating fish feed is made for both carnivorous and graminivorous fishes.

Floating fish feed technology

Based on modern fish feeding requirement and modern technology, the most advanced fish feed manufacturing technique is extrusion technology. Extrusion is a process used to create objects of a fixed cross-sectional profile. Raw materials are pushed or pulled through a die of the desired cross-section. Through the high temperature and high pressure (temperature and pressure is created by the friction between raw materials, screws and barrels), the raw materials touches normal pressure and temperature (NPT) when they are out of die, their structures are changed physically.

Floating fish feed processing line

1. Floating fish feed samples introduction

2. Raw materials: corn meal, wheat flour, rice flour, corn starch, de-oil soya flour, fish meat (or waste), fish meal, animal oil, ash content, wheat bran, allicin, gunk, vitamins, minerals, food color etc.

3. Humidity: the moisture is no more than 15%.

4. Ups and downs properties: floating, half-floating, sinking.

5. Shapes: spherical (pellets), granular, columnar, acetabuliform, pisciform, or customrized.

6. Sizes: (1) diameter: from 1.5mm to 25mm (2) length: user-defined.

Floating fish feed sample

Output can be 150kg/h, 240kg/h, 500kg/h, 1ton---3ton/h

(kg/hr)

Power

(kw)

Power

(kw)

(mm)

Dry

Method

3 Phase

50/60Hz

208/220/240/

380/400/415/

440/480V

1 Phase

50/60Hz

100/110/120/

127/137/220/

230/240V

Wet

Method

Floating fish feed pellet machine extruder

1. Our floating fish feed making machine's extruders are twin-screw extruders, there are one couple of screws inside the barrel. The screws are combined screws, which is economical and practical for users (if screws are abrasive, the user don't need to change whole screws, only change the end part of the screws). The raw material of screws is 38CrMoAl (standard: GB/T 3077-1999), which is processed for nitriding treatment. This material's hardness and strength performance is excellent, which can bear high temperature and high pressure.

2. Our twin-screw extruder has forced lubrication and cooling system. This system can protect gears, axles and bearings, which can increase of service life. We can add cooling system (outside barrels) according to users' request.

3. Our twin-screw extruder has self-clean function. When maintenance, the users don't need to extract the screws. The screws can be cleaned by adding waste material.

4. Except screws, barrels, dies or blades, the other parts touching food is stainless steel or food grade plastic. It is sanitary and safety. (Screws, barrels, dies and blades have to bear high temperature and high pressure, they can't be stainless steel, or they will be broken.)

5. Our extruders, dryers and cutting machines (if any) are equipped with inverters. Our standard inverters' brand is Delta (Taiwan), we can supply the other inverters as per users' requirement, such as LS (Korea), ABB (Switzerland), Siemens (Germany).

6. Our floating fish feed making machine automation degree is high. For small capacity lines, they need 2 workers to operate; for big capacity line, they need 3-4 workers to operate. It can save owner's labor cost. Our expanded fish feed processing lines' field area is small. The machineries can be placed in line, in L shape, even in U shape. It can save users' workshop investment.

Packing:Inside plastic bag, outside wooden case(Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation:Shipping, train, express or upon clients' demands

Company Information:

Company Information:

Jinan Keysong Machinery company is a professional manufacturer of food processing machine. Our products had been exported to more than 40 countries; all the products had been gained very good reputation from the dealer and the users.We specialized in researching and producing fruit and vegetable processing line which is including fruit and vegetable washing machine, peeling machine,slicing machine,chopping machine,sorting machine, mixing machine etc.We will continue to follow the policy of "quality first, reputation first, customer first".And hope to cooperate with much more customers all over the world.

Customer

Our Service:

Service & Installation

support for you