Ce Certificate Automatic Baby Food Making Machine Nutrition Powder

Shandong Nolen Machinery Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Nutrition Powder

- Customized:Customized

Base Info

- Model NO.:ks90

- Type:Twin-Screw Extruder

- Material:304stainless Steel

- Motor Brand:ABB,Siemens Optional

- Power(W):22kw -110kw

- Voltage:220V,50Hz 380V,50Hz

- Main Motor Power:75kw

- Installed Power:82.5kw

- Weight:1500kg

- Heating Method of Dryer:Electric, Gas, Steam, Diesel, Coal

- Raw Material:Cereals Flour ,Corn, Wheat, Rice, Oat, Soy, Sesame

- Function:Nutrition Powder Baby Food

- Warranty:1.5 Years

- Date of Delivery:30-45days

- Worker Needed:2-4 Workers

- After-Sales Service Provided:Field Installation, Commissioning and Training

- Transport Package:Wooden Case

- Specification:20000*3000*2600mm

- Trademark:KS

- Origin:Shandong, China

- HS Code:8438800000

- Production Capacity:800-1200kg,H

Description

Basic Info.

Model NO. ks90 Type Twin-Screw Extruder Material 304stainless Steel Motor Brand ABB/Siemens Optional Power(W) 22kw -110kw Voltage 220V/50Hz 380V/50Hz Main Motor Power 75kw Installed Power 82.5kw Weight 1500kg Heating Method of Dryer Electric, Gas, Steam, Diesel, Coal Raw Material Cereals Flour ,Corn, Wheat, Rice, Oat, Soy, Sesame Function Nutrition Powder Baby Food Warranty 1.5 Years Date of Delivery 30-45days Worker Needed 2-4 Workers After-Sales Service Provided Field Installation, Commissioning and Training Transport Package Wooden Case Specification 20000*3000*2600mm Trademark KS Origin Shandong, China HS Code 8438800000 Production Capacity 800-1200kg/HProduct Description

CE certificate automatic baby food making machine nutrition powder

1. Descriptiom:

Baby food machinery is used to produce infant food and some other instant flour products. The raw material is put in the mixer then mixed ingredients are fed into extruder feeder. The extruder is fitted with: special cylindrical holding silo; vibratory doser with hopper to feed the extruding screw; extrusion mechanism and cutting; independent electric panel.

After the extrusion the product is conveyed till the continuous rotary drier through a pneumatic conveyor. The continuous rotary drier has a heat exchanger with gas burner that allows a better heating of the product and it is economically viable owing the low cost of electric power. Case the client prefers we have the electric drier also.

a. Raw Materials:

This production line adopts cereals flour ,corn, wheat, rice, oat, soy, sesame, walnut, black rice etc.

b. Products:

This line can be used to produce baby food,baby rice, sesame paste,FBF,CSB and samaposha , walnut paste-type products,etc

c. Capacity:

120-150kg/h,160-240kg/h, 300-500kg/h.

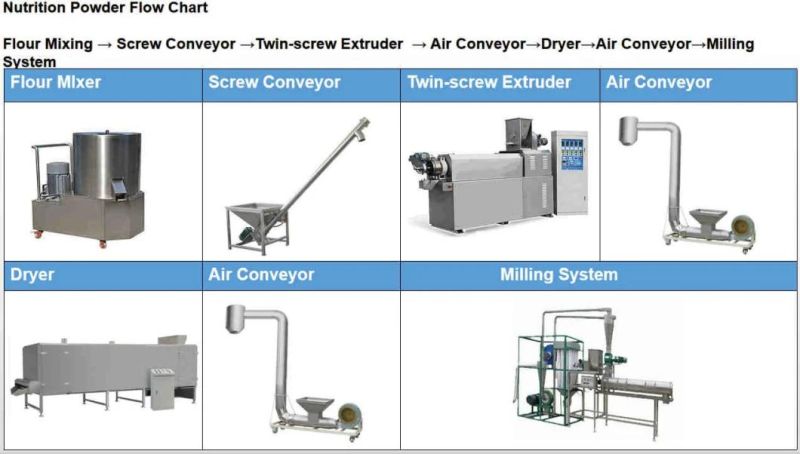

d. Flow chart:

Mixing system---Extrusion system---- Drying system (Frying System) -Milling system----Packing system

e. Voltage:

In China: Three phases: 380V/50Hz, Single phase: 220V/50Hz. We can make it according to customers' Local voltage according to different countries.

f. Machines Materials

All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

g. Technical Parameters

| Model | KS95 | KS90 | KS85 | KS70-1 | KS70 | KS65 |

| Installed Power | 100.7kw | 82.5kw | 92kw | 61.5kw | 46.5kw | 35kw |

| Main Motor Power | 90kw | 75kw | 75kw | 45kw | 30kw | 22kw |

| Capacity | 1500-2000kg/h | 800-1200kg/h | 400-500kg/h | 200-260kg/h | 200-260kg/h | 100-150kg/h |

| Dimension | 4.9×1.2× 2.7m | 4.7×1.2×2.5m | 3.9×1.2×1.8m | 2.8×1.0×1.9m | 2.8×1.0×1.9m | 2.7×0.9×1.8m |

2.Features Of Extruder:

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

b. The extrusion barrel is constructed of carbon steel, is made by 45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. SIEMENS(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

3.Our Services:

#. In the processing of production, our professional technical engineers inspect the processing to ensure the quality of products

#. Every machine must be tested before delivery for 8 hours , all of them are absolutely qualified.

#. 18 months guarantee of the whole machine.

#. Main parts(excluding the consumables) shall be changed free of charge if there is any problem

during the warranty period.

#. Lifetime maintenance free of charge.

#. We will provide the consumable parts at an agency price when you need replacement.

#. Machine has been adjusted before delivery.

#. Our staff can be sent to your company to install or adjust if necessary

4.Packaging and shipping:

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottomWith this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

5.About US: