Automatic Floating Fish Feed Pellet Pet Food Making Machine

Shandong Nolen Machinery Co., Ltd.- Certification:CE, ISO9001, SGS

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

Base Info

- Model NO.:KS70

- Capacity:120-1000kg,H

- Snack Extruder:Twin Screw Extruder

- Machine Material:Stainless Steel

- Motor:Siemens

- Inverter:Delta

- Electric Parts:ABB

- Control:Manual or PLC

- Delivery:15-30 Days

- Warranty:1.5 Years

- Transport Package:Wooden Case

- Specification:30000*1300*2500mm

- Trademark:KS

- Origin:Shandong, China

- HS Code:8438800000

- Production Capacity:50 Set,Month

Description

Basic Info.

Model NO. KS70 Capacity 120-1000kg/H Snack Extruder Twin Screw Extruder Machine Material Stainless Steel Motor Siemens Inverter Delta Electric Parts ABB Control Manual or PLC Delivery 15-30 Days Warranty 1.5 Years Transport Package Wooden Case Specification 30000*1300*2500mm Trademark KS Origin Shandong, China HS Code 8438800000 Production Capacity 50 Set/MonthProduct Description

Automatic Floating Fish Feed Pellet Pet Food Making Machine1. Product Description

Hot sale stainless steel fish food equipment / poultry food making machine / pet feed meal machine uses meat meal, fish meal, corn powder, soya meal and other grains powder as main materials to make the pet food, such as dog, cat, fish, bird food etc. With different shapes and tastes by changing the dies and formulations. The pet foods are made under high temperature condition, and popular to the pet food market.

1.Raw Materials: Meat Meal, Fish Meal, Corn Powder, Soya Meal and Other Grain Powder

2.Products: Pet Food, Like Dog, Cat, Fish, Bird Food etc. with Different Shapes and Tastes by Changing the Dies and Formulations.

3.Capacity: 120-150 KG/H, 200-250 KG/H, 400-500 KG/H, 800-1000 KG/H.

4.Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage according to different countries.

5.Machines Materials: All the machines are made by food grade stainless steel

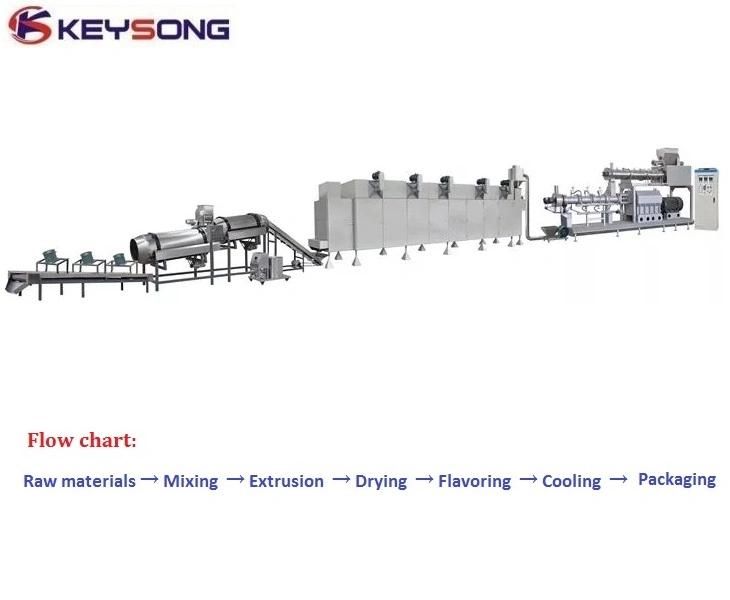

Flow chart

grinding→mixing→extruding→drying→flavoring→cooling→packaging

Raw material

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

Fish feed product

fish feed pellet: floating/sinking

diameter from 0.2mm to 20mm

Fish feed advantages

In order to meet modern fish farms development, most of modern fish feed is made by twin-screw (or single screw) extrusion production line, which is called expanded, extruded or puffed fish feed.

Adopting cereals, vegetable proteins, vitamins, minerals, fish meal and fish oil as raw materials, and adopting dry-type or wet-type extrusion as manufacturing technique, expanded fish feed is made for both carnivorous and graminivorous fishes.

Compared with traditional fish feed, expanded fish feed has the advantages:

(1) easier feeding management

(2) lower wastage rate

(3) lower water contamination

(4) higher feed nutritional ingredient use ratio

(5) longer storage time. Expanded fish feed improves digestibility and refined the balance of nutrients to match the needs of the different species of fish more precisely at different periods of development. At the same time, expanded fish feed improves the sustainability of the ingredients used. Based on the advantages, expanded fish feed will replace traditional fish feed in the future.

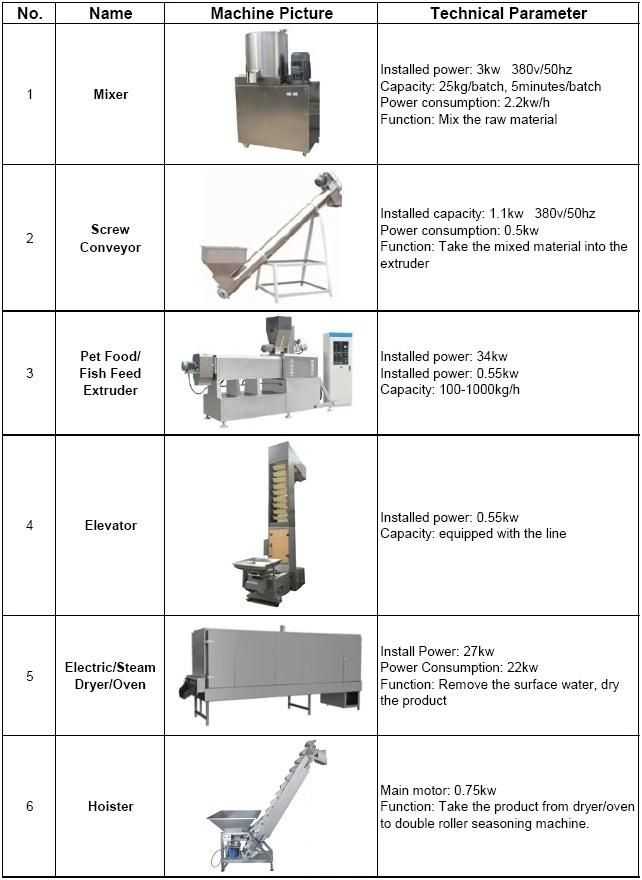

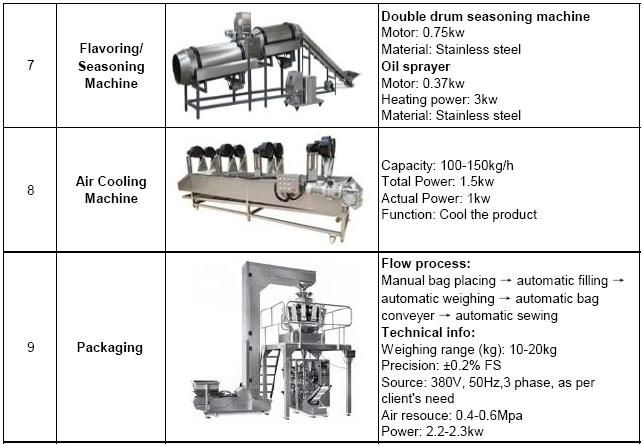

Equipment list in the fish feed production line

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

Technical Parameters

| Model | KS 65 | KS 70 | KS 85 | KS 95 |

| Install Power | 65KW | 110KW | 190KW | 250KW |

| Consumption Power | 42KW | 77KW | 133KW | 175KW |

| Output | 120-150KG/H | 220-260KG/H | 500-600KG/H | 900-1000KG/H |

| Dimension | 19000×1300×2200mm | 22000×1300×2200mm | 30000×1300×2500mm | 38000×1300×3000mm |

Our Service

We Provide Satisfied Service & Turnkey Solution:

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

Packing and shipping

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottomWith this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

Our Factory/Plant

Our Customers

FAQ

1. Are you a factory or trading company?

We are the manufacturer with more than10 years' experience. As only the machine made by ourselves, quality can be trusted, and most important thing is we can do better service after sales. We know how to fix the problem in each parts easily.

2. How long is the delivery time?

For standard machines, it would be 7-10 days; For non-standard machines and customized machines according to client's specific requirements, it would be 15-30 days.

3. How should I pay for my order? what is the procession of this purchase?

30% advance payment by T/T, the rest 70% before the shipment.

We will arrange the production after receiving your advanced payment. When the machine is ready, we will send you pictures.

After we got the rest payment, we will ship the machine to you.

4. How about your service after sales? Can your engineer speak fluent English?

We offer the service from you received the machine, including installation of the machine,

how to use machine? how to let machine work? usually we will teach you how to do by email or by Skype. Our engineer has many years of experience for CNC machine service. he can speak very good English, so he can solve the problem in short time.

5. How about the documents after shipment?

After shipment,well send all original documents to you by DHL, including Packing List, Commercial Invoice, B/L, and other certificates as required by client.