High Output Customized Bread Crumb Making Machine

Shandong Nolen Machinery Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

Base Info

- Model NO.:KS65-III

- Raw Material:Rice Flour, Corn Flour, Soybean Flour etc.

- Materials:Stainless Steel Good Grade

- Motor:Siemens, ABB or Chinese Brand

- Warranty:One Year

- Energy:Electric , Diesel , Gas

- Main Extruder:Twin Screw Extruder.

- Delivery Time:15-30days

- After Sale:24hours

- Function:Multi Functional

- Package:Wooden Case

- Transport Package:Wooden Case

- Specification:18000*1200*2200mm

- Trademark:KS

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:50sets,Month

Description

Basic Info.

Model NO. KS65-III Raw Material Rice Flour, Corn Flour, Soybean Flour etc. Materials Stainless Steel Good Grade Motor Siemens, ABB or Chinese Brand Warranty One Year Energy Electric / Diesel / Gas Main Extruder Twin Screw Extruder. Delivery Time 15-30days After Sale 24hours Function Multi Functional Package Wooden Case Transport Package Wooden Case Specification 18000*1200*2200mm Trademark KS Origin Shandong China HS Code 8438800000 Production Capacity 50sets/MonthProduct Description

High Output Customized Bread Crumb Making MachineDescription:

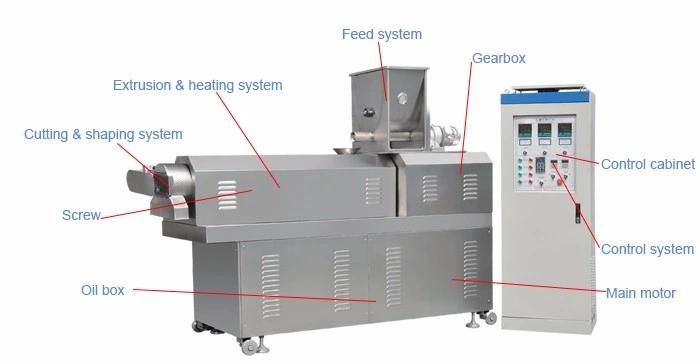

The bread crumbs processing line developed by our company. Bread crumb.is mainly used for beefsteak and drumstick as frying dressing .The long and sliver-shaped breadcrumbs are of porous structure inside .After frying ,the crumbs become straight up bit by bit.They are not only puffed and nice in appearance but also crisp and delicate in taste.Breadcrumbs processing line is specially designed and development according to market demand .The whole line can be finished from the raw material ,extrusion ,drying to finished products automatically.

Introduction:

Flow Chart:Flour Mixer→Screw Conveyor→Double Screw Extruder→Cutting Machine→Hoister→Wet Miller→Vibrate→Sifter→Air Conveyor→Dryer→Air Conveyor→Round Vibrate Sifter.

Technical Parameter:

| Model | KS65-II | KS70-II |

| Installed Power | 65kw | 85kw |

| Power Consumption | 30-45kw | 40-60kw |

| Throughput | 100-150kg/h | 200-250kg/h |

| Dimension | 18000*1200*2200mm | 21000*1500*2200mm |

Mix all raw material, rice flour, wheat flour, corn flour, bean flour and other types of flour.

Capacity: 3kw 100-150kg

4kw 150-300kg/h

7.5kw 300-500kg/h

2, screw conveyor

Transport the raw material from mixer into the extruder.

3, Double Screw Extruder

Technical Parameter:

| Model | KS95 | KS90 | KS85 | KS70-1 | KS70 | KS65 |

| Installed Power | 100.7kw | 82.5kw | 92kw | 61.5kw | 46.5kw | 35kw |

| Main Motor Power | 90kw | 75kw | 75kw | 45kw | 30kw | 22kw |

| Capacity | 1500-2000kg/h | 800-1200kg/h | 400-500kg/h | 200-260kg/h | 200-260kg/h | 100-150kg/h |

| Dimension | 4.9×1.2×2.7m | 4.7×1.2×2.5m | 3.9×1.2×1.8m | 2.8×1.0×1.9m | 2.8×1.0×1.9m | 2.7×0.9×1.8m |

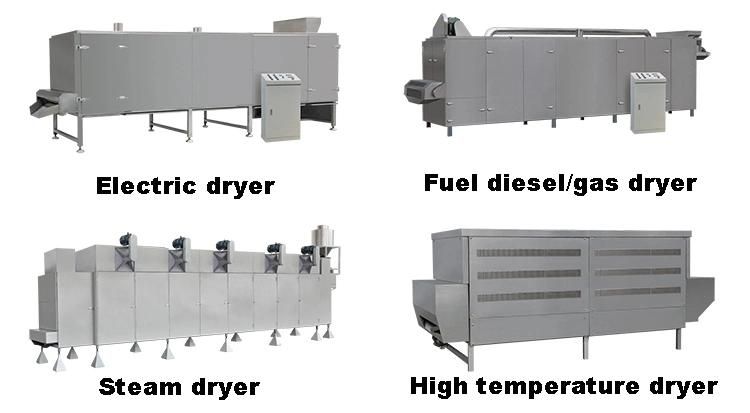

5.Dryer

5.Dryer  Technical Parameter:

Technical Parameter:| Model | Electric(gas/diesel) Consumption | Heating Temperature | Output | Dimension |

| Three-layer electric dryer | 27kw/h | 200°C | 150kg/h | 5400*1300*2000mm |

| Five-layer electric dryer | 45kw/h | 200°C | 300kg/h | 5800*1300*2400mm |

| Three-layer gas/diesel dryer | 7-10L/h | 200°C | 150kg/h | 6500*1600*2000mm |

| Five-layer steam dryer | 28.4kw/h | 200°C | 800kg/h | 9600*1700*3500mm |

| Seven-layer dryer | 48kw/h | 90°C | 100kg/h | 9000*2400*3000mm |

Function: remove the moisture of the puff snacks.

Application:The Tumbler sieve machine is particularly used to classify small materials and fine powder according to its unique structure and working principle. It is not only apply to dry sieving, but also wet sieving. It is widely used in mine, building material, metallurgy, foundry, abrasive material, chemical, light industry, medical, food and other industry.

Food Samples:

Competitive Advantages:

1. Guaranty: One Year.

2. One set of consumable accessories will be provided with the machine.

3. Any question, you can mail/call us at any time. And our most experienced engineers are assigned to give consulting service, and always available for dispatching abroad.

4. All spare parts are always available for delivery.

5. Manual is in English.

6. Minimum order: 1 set

7. Prompt Delivery: 15-20 working days after receiving deposit

8. Installation: sending one technician to the customer's factory for installation and training.

9. Packaging: firstly packing with plastic inner side, then strengthening with wooden case outside.

Company Information:

Keysong was founded in 2013. Specializing in producing food machines for more than 6 years. Since its inception, it is specializing in the manufacture, research, development, sales and after-sales of food extrusion machine, puffed food production line, fruit and vegetable washing and drying processing line.

Our History:

In 2013, Keysong was established, concentrating on manufacturing and selling extrusion snack production line at home and abroad.

In 2014, Keysong broke traditional breakfast cereal production technology, and invented new production process.

In 2015, Keysong moved to a new workshop, which covers the area of 5000 square meters. In 2015, we have our agency in India, Nigeria, Thailand, Morocco and Algeria.

In 2016, Keysong cooperated with Shandong Liwei Microwave equipment, started researching on food microwave drying technology. In August, 2016, Keysong build a team, concentrating on researching on the technology of vegetables and fruits washing, cutting, drying and freezing. And has received great results till now.

Customers:

Factory office:

Our certificates:

About us & more details:

| MOQ | 1 set |

| Supply Ability | 20 sets per Month |

| Shipping port | Qingdao port, Shandong, China |

| Packing details | Fumigation-free wooden case outside, stretch film inner |

| Relevant spare parts | free, delivery with processing line |

| Guarantee | Within 12 months |

| Oversea service | Provide installation and commissioning after machine arrived your factory |

| Payment terms | 30% is paid by T/T as the down payment, 70% is paid by T/T or L/C before shipment. |

| Delivery time | 30 days after receipt the deposit |

| Pre-shipment | When it finished, we will invite you to our company to inspect machines, when no problem, we will arrange the shipment |

1. How about the documents after shipment?

After shipment, we'll send all original documents to you by DHL/TNT, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

For standard machines, it would be20-30 days; For non-standard machines and customized machines according to client's specific requirements, it would be 30-45 days.

3. Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

4. How is the packing?

Water-proof plastic film package with foam protection in each corner Solid Seaworthy Wood Box Package with Steel Belt Save space as much as possible for container loading