Automatic Panko Bread Crumbs Snacks Puff Food Making Machine

Shandong Nolen Machinery Co., Ltd.- Certification:CE, ISO9001, SGS

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

Base Info

- Model NO.:KS-85

- Capacity:150-500kg,H

- Machine Material:Stainless Steel

- Motor:Siemens

- Inverter:Delta

- Control:Manual or PLC

- Food Extruder:Twin Screw Extruder

- Screw Material:38CrMoAl

- Delivery Time:15-30 Days

- Warranty:18 Months

- Services:Turnkey Service

- Transport Package:Wooden Case

- Specification:28000x3500x4000mm

- Trademark:KS

- Origin:Shandong, China

- HS Code:8438800000

- Production Capacity:50 Set,Month

Description

Product Description

(1) Bread crumbs is mainly used for fried breakfast and drumstick as frying dressing.The long and slivershaped breadcrumbs are of porous structure inside. After frying,the crumbs become straighe up bit by bit.They are not only puffed and nice in appearance but also crisp and delicate in taste.

(2) Bread crumbs processing line is specially designed and developed according to market demand.The whole line can be finished from the raw materials,extrusion,drying to finished products automatically.

Technical Parameters

Raw Materials

wheat flour, wheat bran, sugar, salt, egg powder, vitamins, minerals, food color etc.

Capacity

The capacity of our bread crumbs processing line is very reasonable: it can be (150-500kg/hr). And the operation is very simple, the production time is within 20 minutes from raw material to final product.

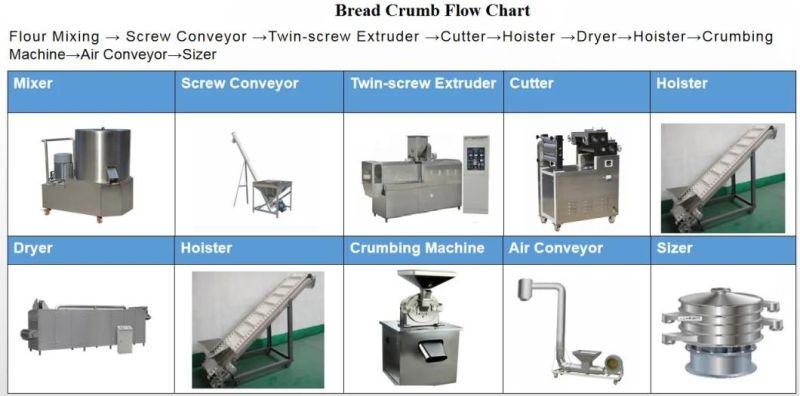

Flow chart

Application

Food additive for deep fried food and mainly for frying food surface, such as: fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious and nutritious.

Bread crumbs extruder----Twin screw extruder

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. World famous brand Siemens main motor, guaranteeing good quality

5. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

Finished bread crumbs pictures

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottomWith this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

Our Factory/Plant

Our Customers

FAQ

1. Are you a factory or trading company?

We are the manufacturer with more than10 years' experience. As only the machine made by ourselves, quality can be trusted, and most important thing is we can do better service after sales. We know how to fix the problem in each parts easily.

2. How long is the delivery time?

For standard machines, it would be 7-10 days;

For customer-made machines, it would be 15-30 days, it depends on clients's specific requirements.

3. How should I pay for my order? what is the procession of this purchase?

30% advance payment by T/T, the rest 70% before the shipment.

We will arrange the production after receiving your advanced payment. When the machine is ready, we will send you pictures.

After we got the rest payment, we will ship the machine to you.

4. How about your service after sales? Can your engineer speak fluent English?

We offer the service from you received the machine, including installation of the machine,

how to use machine? how to let machine work? usually we will teach you how to do by email or by Skype. Our engineer has many years of experience for CNC machine service. he can speak very good English, so he can solve the problem in short time.

5. How about the documents after shipment?

After shipment,well send all original documents to you by DHL, including Packing List, Commercial Invoice, B/L, and other certificates as required by client.